Braber Equipment

Project Details

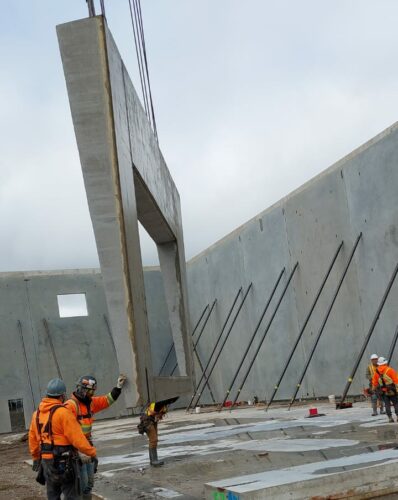

Tilt-Up Construction Boosts Braber Equipment’s Expansion in Ontario

Introduction:

- Braber Equipment Inc. expands its presence in London, Ontario with a new 100,000-square-foot warehouse.

- Tilt-up construction chosen for innovative features, efficiency, and durability.

Benefits of Tilt-Up Construction:

- Lower heating/cooling costs: Tilt-up construction offers energy-efficient solutions.

- Durable concrete walls: Ensures long-lasting structural integrity.

- Speed of construction: Accelerates project completion timeline.

Tilt-Up Construction Process:

- Casting panels: Concrete panels cast on temporary slabs for efficient construction.

- Tilting into place: Panels expertly tilted and lifted into their designated positions.

- Efficient timeline: Exterior walls erected within a week, showcasing the speed of tilt-up.

Challenges Faced and Overcoming Obstacles:

- Supply chain disruptions: COVID-19 impacts material deliveries, leading to delays.

- Delayed start: Pushed from early fall to late fall 2021 due to supply chain challenges.

- Weather issues: Late fall weather conditions impact on-site development.

Overcoming Challenges with Tilt-Up:

- Recouping time: Tilt-up construction expedites the process, mitigating delays.

- Final delay: Project completed with a minimal one-month delay.

Benefits for Braber Equipment:

- Enhanced energy efficiency: Tilt-up construction maintains consistent temperature and humidity control.

- Cost savings: Fewer columns and steel required, resulting in cost-efficient construction.

Conclusion:

- Tilt-up construction proves to be a catalyst for Braber Equipment’s successful expansion in Ontario.

- Despite challenges faced, the innovative features and efficiency of tilt-up construction positively impacted the project’s outcome.

Learn more about Braber Equipment at www.bepowerequipment.com.

Learn how tilt-up construction can benefit your next warehouse facility construction project by reaching out to Len Overbeek, Business Development Manager for Tilt Wall Ontario, at len@tiltwall.ca or 519-602-2990 for a confidential and no-obligation discussion.

Submit your project today Submit a Project – Tilt Wall Ontario Inc.

General

Location & Year

15890 Robins Hill Road, London OntarioGeneral Contractor

MCI Design-Build CorporationArchitect

Concentric EngineeringDeveloper/Client

Braber EquipmentTechnical

Heaviest Wall

135,600 LbsLargest Wall

1,307 Sq FtTotal Sq. Ft. of Panels

53,000# of Panels

60Tallest Panel

46 FeetFloors

1 StoryPanel Finishes

Textured PaintPanel Features

Reveals and Shadow PanelsHave a Project You’d Like to Discuss?

We’d love to hear about it! Send us a few details

and a member of a team will be in touch.

About Tilt Wall

Tilt Wall is a subcontractor committed to bringing a superior building product to the Ontario construction industry since 2001. With its tilt-up construction and design experience it is able to assist their clients design buildings with lasting beauty and value. It takes pride in building lasting relationships, and impacting the lives of those around them in positive ways.